Standard Operating Procedure SOP for Sampling in Process Validation.

1. Objective

1.1 The intention of this procedure is to facilitate the creation of best practices as to the right approach with regard to sampling during process validation. It embraces types of sample, sampling and sample collection, sample handling, analysis, documentation, and reporting that are critical in establishing product quality as well as compliance to regulatory requirements.

2. Scope

2.1 This procedure applies to all sampling procedures involved in process validation in or out of the process, during production or at intermediate stages, as well as final product samples.

3. Definitions

3.1 In-process samples: Specially collected from the production process prior to the end of the final process phase.

3.2 Intermediate samples: A subsample that is taken from an observation point other than the final point in a sequence.3.3 Final product samples: When all the processing the samples are collected after the end of processing from the final products.

4. Responsibilities

4.1 Quality Assurance: Additionally, the sampling plan and procedure are approved by the IRBs in the process.

4.2 Production personnel: I was to take samples according to the sampling plan which was used to determine the procedure to be followed for the sampling.

4.3 Analytical personnel: The sample analysis bear the responsibility of testing method and sample validation.

5. Sampling Plan

5.1 Create a sampling plan which identifies the kind of samples required, their origin, sample interval and quantity to be taken bearing in mind the characteristics of the product and process.

5.2 Always seek permission from the Quality Assurance department before starting the sampling plan.

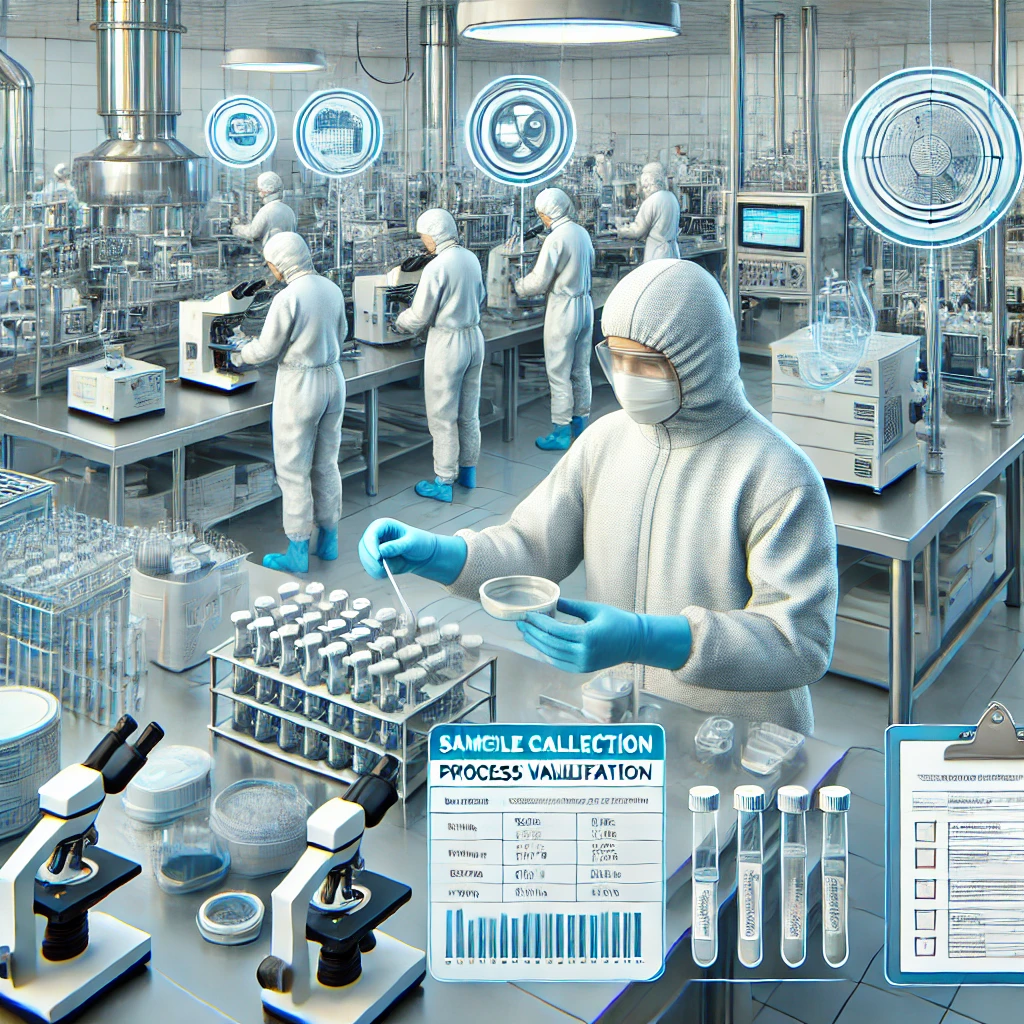

6. Sample Collection

6.1 In-process samples: Sample at the normal time intervals and at dangerous or crucial times in the cycle of production. Record the time period as well as place sample is taken from and size of the sample.

6.2 Intermediate samples: Take sample after a process step and before another process step in the flowchart. Keep the same documentation as with in-process samples.

6.3 Final product samples: Taking samples from many batches of products and shipping containers. Might include lot numbers, and an expiry date, document and make notes.

7. Sample Handling

7.1 Samples stored under appropriate conditions as suggested by original product specifications, as prescribed in GMP specifications. All through the process be sure that samples are correctly labelled and are kept preserved.

7.Sample must be preserved and transported in proper transportation conditions and containers if required.

8. Sample Analysis

8.1 Sample analysis must be done by laboratory methods and equipment which have been proven to be efficient. Use the instructions outline in method and equipment user manual.

8.2 All observations made during the test should be put down rightly and clearly. The done tests and their results are recommended to be stored in a record.

9. Documentation

9.2 There should be a documentation for the sampling busymaking, sample collection, handling, analysis and results for each sampling activity.

9.2 The possession of sampling records and other documents prepared and kept in accordance with the requirements of the relevant Acts of Parliament.

10. Reporting

10.1 Write a report on the sampling result advising if any deviations from the sampling plan were made and action to be taken.

10.2 Share the report with departments which could be impacted upon theme of the report (eg. Quality Assurance, Production, Regulatory Affairs).

10.3 Periodically convey the report’s findings so changes in consistent pattern of results and problems can be identified and the sampling strategy adjusted accordingly.

11. Review and Revision

11.1 Conduct periodic or as when there are modifications in the sampling procedure and plan.

11.3 The procedure and plan are always to be modified with required approval from the Quality Assurance Department.

12. Training

12.1 Meet with procedure and sampling plan to undergo involved train personnel and review where necessary.

12.2 Make all employees understand what their roles are as well as the significance of offering consistent quality products that meet regulatory requirements.

Therefore when a company follows this standard operating procedure of sampling in process validation, then the company can be confident that it is taking all the right steps to meet the high standards of product quality and also dispelling any accreditation from the regulatory departments. Monitoring and analyzing the same regularly will not only indicate the problem but also give the room to correct such problem so that the Process Validation is reliable and consistent.