Dirty HEPA Filters in Pharmaceutical Industry: The Dangers

Introduction

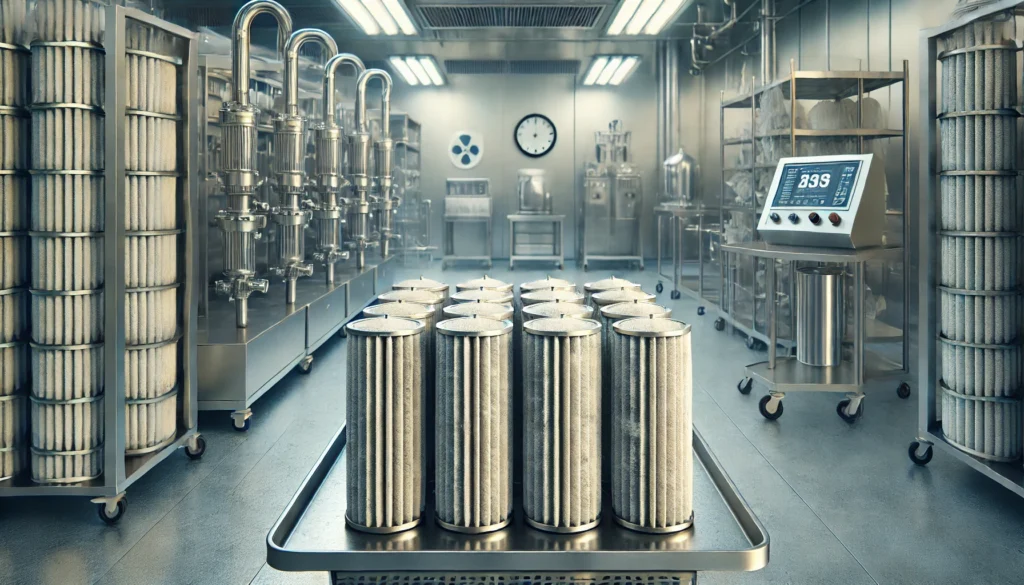

In sphere of medicine the issue of cleanness is rather sensitive for purposing to produce high quality medicines and to minimize the safety risks for workers and customers. There is one indispensable aspect, which helps to maintain cleanliness along with absence of germs in the given environment – utilization of HEPA filters, High-Efficiency Particulate Air. HEPA filters capture particulate matter as small as 0.3 microns with 99.97 percent efficacy to help contain the bacterias, viruses and other pathogens that could infect occupants of a home. Nevertheless, when these filters get dirty, they could be quality and health risks to the pharmacies industry.

Quality Risks

A dirty HEPA filter can negatively impact the quality of the manufactured products in several ways:

1. Contamination: Its main use is to capture and eliminate different types of particles or microorganisms in order not to contaminate the environment in which the product is being manufactured. When filters are worn out or damaged they can no longer trap the particulate matter that may contaminate the manufacturing environment thereby affecting the final product. Poor quality and sometimes infected drugs manufactured as a result of this can be bad for the patients.

2. Deviations from Good Manufacturing Practices (GMP): As a component of the GMP, the phrase HEPA refers to the guidelines on the manufacturing of pharmaceutical products. A polluted HEPA filter can trigger non-compliance with GMP that may lead to penalties and/or revoke product authentication, which eventually may require recall or total shutdown of production.

3. Impaired air quality: Thus if the filter that is use in the plant is a HEPA filter and it becomes dirty it is able to accumulate contaminants in the air and therefore leads to poor quality of air in the manufacturing environment. This all can cause some workers to be uncomfortable, lower output and can increase the likelihood for mishaps like contamination of food products with other products or staining the floor.

Health Risks

In addition to the quality risks, dirty HEPA filters can also pose serious health risks to workers and consumers:

1. Respiratory issues: Impurities captured by the dirty HEPA filter can become occupied by air with the result that workers are at high risk of having respiratory related issues. Irritating such particles, when inhaled they can cause one to cough and respiration problems. In its severest forms, long-term exposure to the substance results in respiratory tract diseases including asthma or bronchitis.

2. Allergic reactions: Dust or mold and other particles that may have accumulation in a dirty HEPA filter can prove to be an irritant to allergic persons, their pets and household members. It can manifest as minor as sneezing or itching or severe as a breathing issue or anaphylaxis.

3. Increased risk of infections: Dulled filters can enable microorganisms, including bacteria or virus, to circulate inside the manufacturing air. This can endanger the lives of workers thereby contracting diseases such as flu and in the severe cases pneumonia.

4. Possible bioaerosol exposure: In pharmaceutical manufacturing, bioaerosols are airborne particles containing living microorganisms or their waste products: In the drug manufacturing industry, endotoxins are substances that can be present in the air in the form of bioaerosols. When these filters are filled with such bioaerosols, they can distribute the particles across the facility, increasing the risk of being affected by diseases.self || britishcouncil.org Digital media and technology have opened a new avenue for the spread of fake news, provided the so-called clean-filter HEPA bioaerosols with dangerous pathogenic microorganisms such as anthrax, salmonella or COVID 19.

Realizing Quality and Health Benefits

To mitigate the quality and health risks associated with dirty HEPA filters, pharmaceutical companies should implement several preventive measures:

1. Regular monitoring and maintenance: Check the face of the HEPA filters for cleanliness and wear and tear and follow the manufacturer recommendations for changing it or cleaning it. The checks must preferably involve inspection for any tear or holes, and confirmation of the correct installation and proper sealing of the filters.

2. Proper training: HEPA filter handling, installation and maintenance, need to be adequately trained to supervisors and employees doing all of the above in order not to compromise the condition of the HEPA filters.

3. Replacement schedules: They also should change filters according to the manufacturer’s recommendation to effectively filter the contaminants. This varies and therefore may need to change often and especially whenever particular filter model or sometimes when the air contained in the facility is polluted to different levels.

4. Airborne particulate testing: Comprehensive assessment test should be performed in order to determine the levels of airborne particulate concentrations in the facility. Determinations may be made regarding when in the HEPA filter’s life cycle that replacement of filter, or some other remedial action, may be necessary.

5. Engineering controls: Apart from right filtering, other precautions to reduce the risk of cross contamination in industries engaged in production of pharmaceutical products include establishment of pressure enclosures, buffer zones, and air showers respectively.

Conclusion

Contaminated HEPA filters present relevant quality and health hazards to the pharmaceutical business, affecting the quality of produced pharmaceuticals, as well as the health of employees and customers. Through a stringent maintenance policy and .employee training and constant monitoring and evaluation, these risks can be minimized thus arriving at a high standards of hygiene of both the pharmaceutical products as well as the employees.